EJT-Tekniikka Oy is a machine shop and a reliable subcontracting partner for the marine industry, delivering high-quality steel parts and welded structures tailored to customer needs. A versatile machine fleet enables the entire production chain to be carried out by a single operator – from weld edge preparation to surface-treated end products.

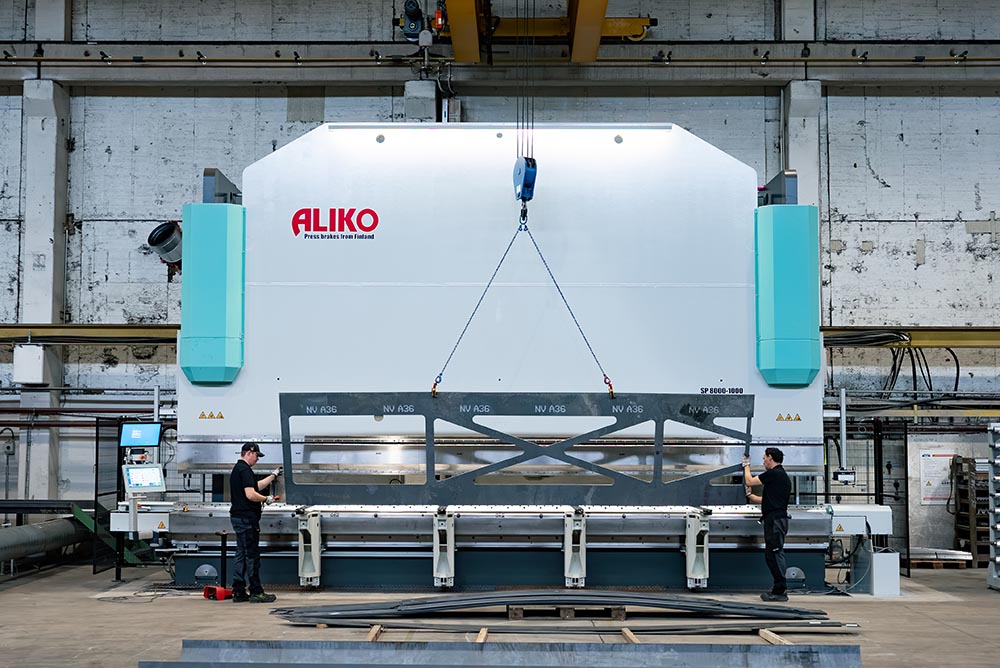

The latest machine investments supplied by Aliko to EJT Tekniikka, the Aliko SP8000-1000 Giant and the Cutlite Penta Plus Bevel, are precision acquisitions tailored to the company’s requirements. Together, they enable the efficient and accurate production of even larger and more complex structures under one roof.

Delivered in spring 2025, the Aliko SP8000-1000 Giant press brake provides everything required for the efficient and precise bending of large components. High bending quality is ensured by an Aliko CNC Vario die and a KMJ automatic angle measurement system. The handling of bendable materials is supported by 9-axis back gauges and four Heavy Duty front supports. This investment in a press brake has enabled EJT-Tekniikka to expand its product range to include parts made of wear-resistant and higher-strength steels.

Production planning is supported by Metalix MBend, designed specifically for office use. The software searches for the necessary bending tools, defines the bending sequence and simulates the process in 3D. Once defined, the ready-made bending program can be transferred directly to the press brake control. The office-based software frees the operator for production work and facilitates production management.

Delivered to Turku in summer 2024, the Cutlite Penta Fiber Plus Bevel laser combines a large cutting area, a powerful laser source, and a bevel cutting head. The cutting table measures an impressive 13 meters in length and 3.5 meters in width, with a cutting power of 20 kW. The bevel head allows various welding bevels to be cut efficiently and with high precision. Thanks to the new laser cutter, the service offering has been expanded to include stainless steel grades and aluminum cut parts, while the cutting thickness has increased to an impressive 50 mm.

Aliko SP8000-1000 Giant

- Bending length – 8000 mm

- Bending force – 1000 tn

- Aliko CNC Vario die V50-300

- Heavy Duty front supports

- Aliko KMJ automatic angle measurement system

- 9-axis back gauge

- Metalix MBend

- Lazer Safe

- Linelaser

- Delivered 2025

Cutlite Penta Plus

- Cutting width 3500 mm

- Cutting length 13000 mm

- Cutting power 20 kW

- Bevel cutting head

- Delivered 2024